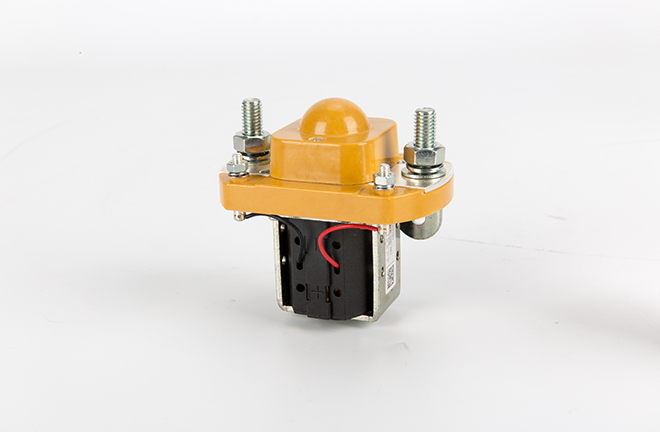

DC magnetic contactors, including solenoid type, double throw, and single pole contactors, are essential components for controlling direct current (DC) electrical loads. Specifically designed for electric vehicles and other high-voltage applications, these 1000V DC contactors play a crucial role in ensuring safe and efficient power management. Whether it's a single pole solenoid contactor or a more complex configuration, DC magnetic solenoid contactors are integral to the reliable operation of DC systems.

Single pole contactors are designed for simple on/off control, while double throw contactors offer the flexibility to switch between multiple circuits or devices.

Efficient power transmission - DC contactors can transmit electrical power with less loss compared to AC contactors.

Precise control - DC contactors offer better control over the motor's speed and torque, making them ideal for applications that require precise movements or positioning.

Longevity - With fewer moving parts than mechanical switches, DC contactors tend to have a longer lifespan.

Low maintenance - Because they have no contacts that wear out, DC contactors are less likely to require maintenance or replacement.

Quiet operation - DC contactors produce less noise during operation compared to AC contactors.

The cost and availability of the contactor should also be considered, as well as any special features that may be required, such as built-in overload protection or low-noise operation. When selecting a DC contactor, the following factors should be considered.

Rated current: The rated current of the contactor should be suitable for the maximum current flowing through the electrical system.

Rated voltage: The rated voltage of the contactor should match the voltage level of the application.

Coil Voltage: The coil voltage should match the voltage levels available in the electrical system.

Duty Cycle: The duty cycle of the contactor should be appropriate for your application.

Environmental conditions: The contactor should be able to operate under the environmental conditions in which it is used.

Certification: Contactors should be certified to safety and environmental standards such as UL, CE or RoHS.

GET A QUOTE