·100A Contact switch capacity, Small volume;

·A set of bridge type N.O.contacts contact circuit has "+", "-" polarity;

DH100 High Voltage DC Contactor

■ FEATURE

·100A Contact switch capacity, Small volume;

·A set of bridge type N.O.contacts contact circuit has "+", "-" polarity;

·Application:Telecom equipment、Solar system、 Engineering machinery、Electromobile、Electric vehicle、Charging system、Train、Ships、UPS etc.;

·Safety Approvals:CCC

·Comply with the ROHS

■ SPECIFICATION

|

Product No. |

DH100 |

|

Contact type |

1H(SPST-NO) |

|

Rated load current of contact(Resistive load) |

100A(DC-1) |

|

The max switch current |

1000A(320VDC) 1次 |

|

Contact voltage drop |

≤80mV@100A |

|

Switching voltage |

12~900V DC |

|

Standard pick-up time (including contact bounce) |

Max. 25ms. |

|

Contact bounce time |

Max. 6ms. |

|

Release time |

Max. 10ms. |

|

Vibration(Sinusoid、80~2000HZ、peak) |

(80~2000)HZ,≤20g |

|

Shock(11ms,1/2 Sinusoid、peak、pick-up) |

≤20g |

|

Operating ambient temperature |

-40℃~+85℃ |

|

Storage ambient temperature |

-55℃~+65℃ |

|

Relative humidity |

20%~90% RH |

|

Insulation resistance |

Min. 100MΩ @ 500VDC |

|

Dielectric strength (Between Insulated Electric Parts) |

2200VAC 50 Hz/60 Hz (1 minute) |

|

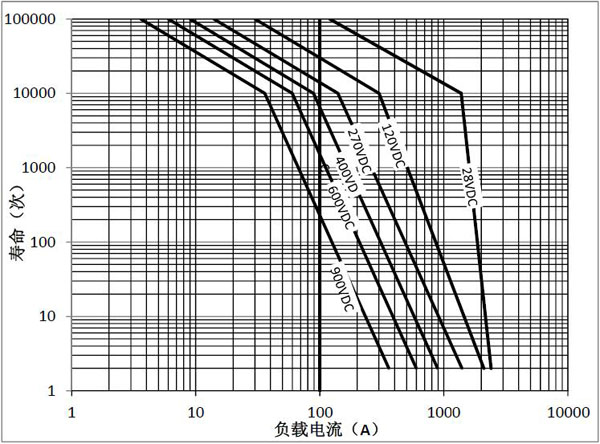

Electrical life |

Please refer to diagram of resistance load life |

|

Mechanical life |

300,000times |

|

Mounted direction |

Any direction |

|

Pollution level |

Ⅲ |

|

Working duty |

Continuous |

|

Weight |

About 0.2kg |

|

P/N |

Coil voltage(V) |

Coil operating voltage (V) |

Pick-up voltage (V) |

Release voltage (V) |

Maintain current (A) |

Coil power (W) |

|

DH100 |

12 |

0.85US~1.1US |

≤9 |

≥1 |

≤0.6 |

8 |

|

24 |

≤18 |

≥2 |

≤0.3 |

|||

|

48 |

≤36 |

≥4 |

≤0.16 |

|

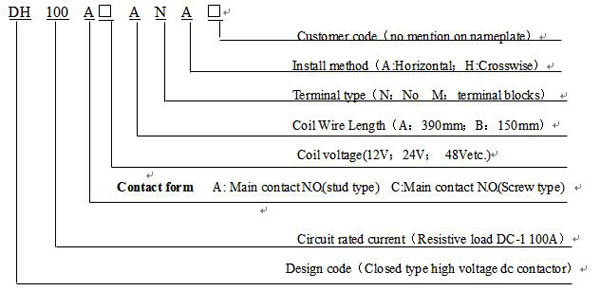

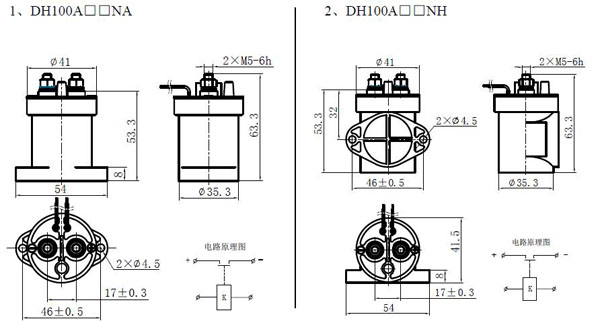

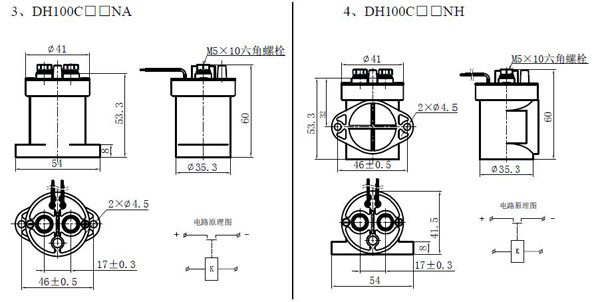

Dimension(mm) |

Tolerance grade not noted(mm) |

|

0~30 |

±0.3 |

|

30~60 |

±0.5 |

|

60~100 |

±1 |

|

大于100 |

±2 |

NOTE: The main contact are polarized; Connect “+” polarity to the main contact terminal with “+” mark, and connect “-” polarity to the main contact terminal with “-” mark.

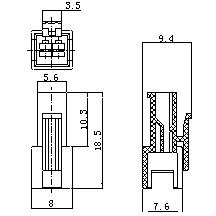

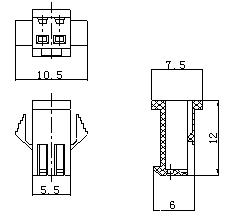

■ Accessory

DH100series product with terminal part no is: DH100□□□M□□,the additional code means terminal type.

| Additional code: M3 Terminal type: SM-2A-HW Terminal type: SMY-HW Terminal dimension figure: |

Additional code: M4 Terminal type: SM-2Y-HW Terminal type: SMA-HW Terminal dimension figure: |

|

|

| Fitted socket type: SM-2Y-HW Fitted terminal type: SMA-HW |

Fitted socket type: SM-2A-HW Fitted terminal type: SMY-HW |

▇ PRODUCT USE INSTRUCTIONS

1、Do use washer when installing the contactor in case the screw fall off. Refer to the following specified range of tighten screw torque, the products may be broken if exceed beyond the maximum torque:

The torque of contact(M5 nut):3.5~4.5N.m

The torque of installing:2.3 N.m

2、The coil is polarized, it should be wired according to the product mark; The contact points are also polarized; it should be also wired according to the product mark. There is a reverse surge absorbing circuit in the energized board, so there is no need to use surge protector any more. We suggest installing a piezoresistor as a surge protector in the contactor which without energized board. However, please avoid using diode, because it will reduce the contactor’s switching capacity.

3、Do not use the product which have been dropped off.

4、Avoid to install the products in strong magnetic field (near the transformer or magnet), or close to the thermal radiation of the objects.

5、Electrical life

This contactor is a kind of high-voltage DC switch; it might be lost the function of cutting off in its final breakdown mode. Therefore, do not use in the condition of exceeding its’ switching capacity and life parameters (please treat it as a product with a specified life and need to be replaced if necessary). Once the contactor loose the function of disconnect and cutting, it could cause the burning of surrounding parts, so it should have a good design of circuit diagram, ensure the power supply can be cut off in 1 second.

6、The diffusion life of internal gases

This contactor designed with gas-tight silo contact point, there is gas in the silo, the diffusion life of gas is decided by the silo temperature(that is Environment Temperature + Temperature rising of the contact electrical), therefore, please make sure the environment temperature should be between -40℃ and +85℃.

7、If the contactor’s coil and contact point is energized continuously with rated voltage (or current),the power is cut off and turned on immediately, at this time due to the coil temperature increases, the resistance of the coil will increase too, so as to cause the pick-up voltage increased, it may cause beyond the rated pick-up voltage , in this case, please take following measures, such as: Reduce the load current, limited duration electricity or Use the higher coil voltage than the rated pick-up voltage.

8、The main contact rated parameters is available at resistance load, if use inductive load (L load) and at the same time the L/R > 1 ms, it should be paralleled a surge current protection device for the inductive load.

9、Product coil drive circuit of power must be larger than the product coil power, otherwise it will reduce the product’s cutting ability.

10、Be careful not to let the debris or oil pollute the main terminal, and the lead-out wire terminal should be reliable contact with the main terminal, or the terminal would be highly heated. At the same time, the lead wire which connected to the product must achieve its conductive capability, to prevent overheating and impact the electrical life. (The wire sectional area of connecting main contact should be more than 35mm2).

GET A QUOTE