Introduction

High current shunt resistors, often called high current ammeter shunts, are essential components in electrical measurement systems. They enable accurate measurement of high currents by converting part of the current into a measurable voltage drop. This article explores their operating principles, applications, types, and selection criteria.

What are high current shunts?

A shunt is a low-ohmic precision resistor connected in parallel with an ammeter or measurement device. When a high current flows through the shunt, a small voltage drop is developed across the shunt (according to Ohm's Law: V = I × R), which is then measured and scaled to determine the actual current.

Key Features:

Low resistance values (usually measured in milliohms or microohms)

High current handling (from tens of amps to thousands of amps)

Precise tolerances (typically 0.1% to 1%)

Temperature stability to minimize drift

How high current ammeter shunts work

A DC ammeter shunt is a device that measures high currents (10A or more) by shunting most of the current away from the ammeter. Here's how it works:

The shunt forms a parallel path next to the ammeter

Most of the current flows through the shunt instead of the ammeter

The shunt converts the high current into a small, measurable voltage drop (typically 50-100mV)

The ammeter then measures this voltage, which corresponds to the actual current

This allows standard ammeters to safely measure high currents that they cannot handle directly.

Applications of shunt resistors

Battery Management Systems (BMS): Monitor charging and discharging currents in electric vehicles and renewable energy storage.

Industrial Power Supplies: Measure high DC/AC currents in manufacturing equipment.

Motor Control: Ensures high-power motors run efficiently.

Energy Meters: Used in smart grids for accurate power consumption tracking.

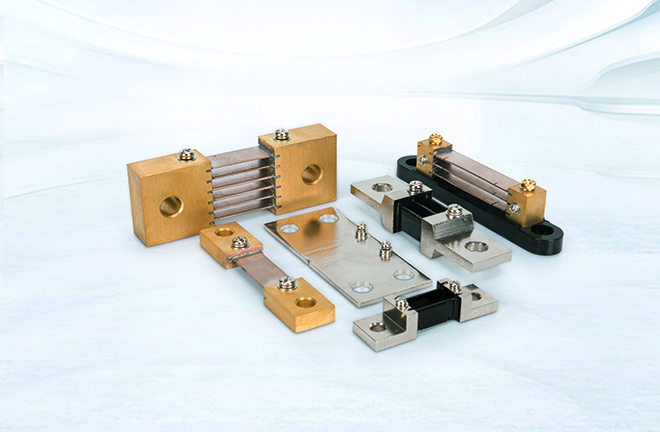

Types of High-Current Shunts

1. Manganese-Copper Shunts:

Made from Manganese-Copper Alloy (Cu-Mn-Ni) with low thermal drift.

Used in precision laboratory instruments.

2. Copper Shunts:

Cost-effective, but with a high temperature coefficient.

Commonly used in automotive and industrial applications.

3. Foil and Plate Shunts:

Designed for very high currents (500A to over 10kA).

Commonly used in power distribution systems.

4. Surface Mount (SMD) Shunts:

Compact PCB mount shunts for low current applications.

Advantages of Using Shunts

Cost-effective – More economical than Hall Effect or Current Transformer solutions.

High Accuracy – Ideal for DC and low frequency AC measurements.

Easy Integration – Works with standard voltmeters and data loggers.

Limitations

Power Loss – Very high currents generate heat.

Isolation Issues – Unlike current transformers, shunts lack galvanic isolation.

Conclusion

A high current shunt is a precision low-resistance device used to measure large electrical currents by converting a known portion of the current into a small, measurable voltage drop. It operates based on Ohm’s Law (V = I × R), where the current passing through the shunt generates a proportional voltage that can be read by a voltmeter or data acquisition system.

For applications that require ultra-high accuracy, manganese copper shunts are ideal, while copper or plate shunts provide robust performance in industrial environments.