Working condition

3.1 Altitude:≤2000m

3.2 Operation temperature:-40℃~+85℃

3.3 Humidity:≤95%

3.4 Service place without explosive media, gas and dust which are corrosive and conductive.

3.5 Be mounted free from rain and snow.;

Application

BA series circuit breaker for equipment (hydraulic-magnetic circuit breaker) is used in the power system with rated current up to 50A, rated voltage up to AC240/415V (50/60Hz) or DC80V. It provides overload, short circuit protection. It can also be used for infrequent close or open. The application fields are computer and peripheral equipment, industrial automatic control system, telecom equipment, power supply system, UPS, railroad, marine, spacecraft, elevator, portable power supply and so on。

Specification

2.1 Standards: IEC60934 , GB17701 , UL489A, UL1077,UL489

2.2 Rated working voltage: DC80V、 AC120/240、AC240/415V、AC250V、AC277/480Y

2.3 Mechanical/Electrical endurance: 10000/6000,(UL489A approved at electrical endurance: 1000)

2.4 Dielectric strength: the main circuit: 3000V, the auxiliary circuit: 1000V

2.5 Certificates: CCC, CE, TUV, VDE, UL1077, UL489A, UL489

2.6 Auxiliary contact: AC250V 5A

2.7 Rated breaking capacity Icn:

|

Rated voltage (V) |

Rated current (A) |

Number of poles |

Breaking capacity (A) |

||||

|

TUV, CE, CCC |

UL1077 |

UL489A |

UL489 |

||||

|

Icn |

Inc |

||||||

|

DC80 |

0.5-50 |

1,2,3 |

4000 |

5000 |

5000 U2 |

5000 |

/ |

|

AC250 |

0.5-50 |

1 |

4000 |

5000 |

/ |

/ |

/ |

|

AC415 |

0.5-50 |

2,3 |

4000 |

5000 |

/ |

/ |

/ |

|

AC120/240 |

0.5-30 |

1,2,3 |

/ |

/ |

5000 U2 |

/ |

5000 |

|

AC240 |

0.5-50 |

1 |

/ |

/ |

5000 U2 |

/ |

/ |

|

AC277/480Y |

0.5-50 |

1,2,3 |

/ |

/ |

2000 U2 |

/ |

/ |

2.8 Resistance:

|

CURRENT(A) |

RESISTANCE (DC) |

RESISTANCE (AC) |

CURRENT(A) |

RESISTANCE (DC) |

RESISTANCE (AC) |

|

1 |

1.63 |

1.69 |

10 |

0.026 |

0.028 |

|

2 |

0.415 |

0.425 |

12.5 |

0.020 |

0.021 |

|

3 |

0.175 |

0.188 |

15 |

0.013 |

0.014 |

|

4 |

0.113 |

0.116 |

20 |

0.008 |

0.009 |

|

5 |

0.077 |

0.078 |

25 |

0.004 |

0.005 |

|

7.5 |

0.039 |

0.039 |

30 |

0.003 |

0.003 |

|

Notes: DCR and impedance based on 100% rated current applied and stabilized a minimum of one hour |

|||||

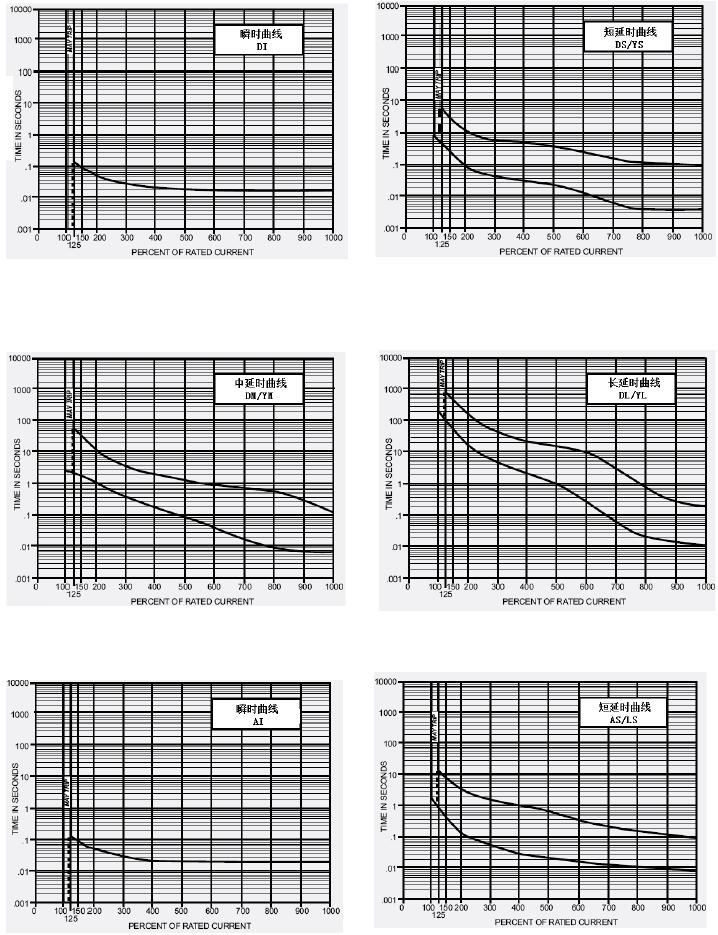

Tripping characteristic

4.1 Tripping timetable (in seconds)

|

Current Curve |

100% |

125% |

135% |

150% |

200% |

400% |

600% |

1000% |

|

DI |

No trip |

0.12max |

/ |

0.1max |

0.05max |

0.022max |

0.017max |

0.017max |

|

DS/YS |

No trip |

0.5-6.5 |

/ |

0.3-3 |

0.1-1.2 |

0.031-0.5 |

0.011-0.25 |

0.004-0.08 |

|

DM/YM |

No trip |

2-60 |

/ |

1.8-30 |

1-10 |

0.15-2 |

0.04-1 |

0.006-0.1 |

|

DL/YL |

No trip |

80-700 |

/ |

40-400 |

15-150 |

2-20 |

0.23-9 |

0.012-0.2 |

|

AI |

No trip |

0.12max |

/ |

0.1max |

0.05max |

0.022max |

0.017max |

0.017max |

|

AS/LS |

No trip |

0.7-12 |

/ |

0.35-7 |

0.13-3 |

0.03-1 |

0.015-0.3 |

0.008-0.1 |

|

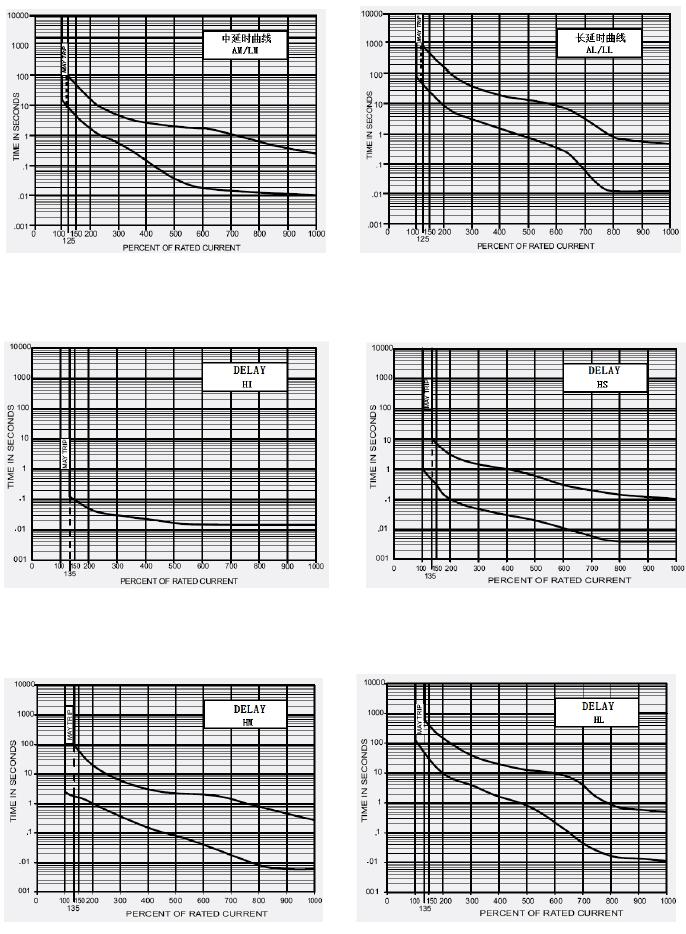

AM/LM |

No trip |

10-120 |

/ |

6-60 |

2-20 |

0.2-3 |

0.02-2 |

0.01-0.25 |

|

AL/LL |

No trip |

50-700 |

/ |

30-400 |

10-150 |

1.5-20 |

0.4-10 |

0.13-0.5 |

|

HI |

No trip |

/ |

0.12max |

0.1max |

0.05max |

0.023max |

0.016max |

0.015max |

|

HS |

No trip |

/ |

0.44-10 |

0.3-7 |

0.1-3 |

0.03-1 |

0.012-0.3 |

0.004-0.1 |

|

HM |

No trip |

/ |

1.8-100 |

1.7-60 |

1-20 |

0.15-3 |

0.04-2 |

0.006-0.28 |

|

HL |

No trip |

/ |

50-600 |

30-400 |

10-150 |

1.8-20 |

0.22-10 |

0.011-0.5 |

4.2 Tripping curves

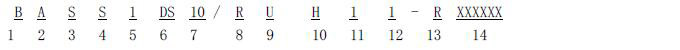

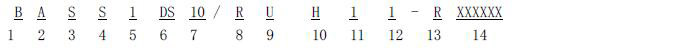

Model and Implication

|

No. |

Implication |

BA |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

1 |

Product code |

B:Circuit Breaker |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

2 |

Design code |

A: Type Code |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

3 |

Circuit |

A:Series trip (Current) V: Series trip (Voltage) T: Relay Trip S:Switch |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

4 |

Actuator code |

S:Long handle , One per Pole L:Long Handle ,One per multiple unit M: Mid Trip Handle D:Short Handle Y: Rocker Handle R:Flat Rocker Handle |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

5 |

Number of Poles |

1:One pole 2:Two poles 3:Three poles |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

6 |

Tripping curve |

DI:DC Instantaneous DS: DC Short DM: DC Medium; DL: DC Long YS: DC Short,Hi-inrush YM: DC medium, Hi-inrush YL: DC long, Hi-inrush AI: AC Instantaneous AS:AC Short AM:AC Medium AL: AC Long LS: AC Short, Hi-inrush LM: AC Medium, Hi-inrush LL: AC Long, Hi-inrush HI: AC/DC Instantaneous HS: AC/DC Short HM: AC/DC Medium; HL: AC/DC Long |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

7 |

Rated current(A) |

0.5~50 |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

8 |

Mounting method |

M:M3 screw mounting; U:6-32UNC screw mounting; Q:Snap-in face plate adapter |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

9 |

Wiring method |

NO or H: Solder-in/ Q.C.tab type B: Push-in stud wiring P: M4 Screw type wiring E: 8-32UNC Screw type wiring J: 8-32UNC Screw wiring with upturned lugs R: M4 Screw wiring with upturned lugs L : M5 Screw type wiring G:10-32UNC Screw type wiring F:M5 Screw wiring with upturned lugs K:10-32UNC Screw wiring with upturned lugs |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

10 |

Actuator & legend color |

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

11 |

Indicate Direction |

With current rating :A, Vertical; B, Horizontal; C, Indicate On Vertical Legend; D, Horizontal On Vertical Legend; E, Indicate Off Vertical Legend ;F,Horizontal Off Vertical Legend G:Indicate Off Vertical Legend with guard ; Without current rating :1, Vertical; 2,Horizontal; 3, Indicate On Vertical Legend ;4, Horizontal On Vertical Legend; 5,Indicate Off Vertical Legend ;6, Horizontal Off Vertical Legend; 7,Indicate Off Vertical Legend with guard ; |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

12 |

Accessory code |

0:No accessory;1:Auxiliary Switch ;2:Trip Alarm Switch; A:Barrier |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

13 |

Certificate code |

E :CCC、 UL1077、CSA、TUV; T: CCC、 UL489A、TUV; J: CCC、 UL489、TUV; |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

14 |

Suffix code |

Identification number (Additional option) Five or more numeric digits, for different variations which is cross referenced to product ordering codes in option |

Dimensions and wiring method

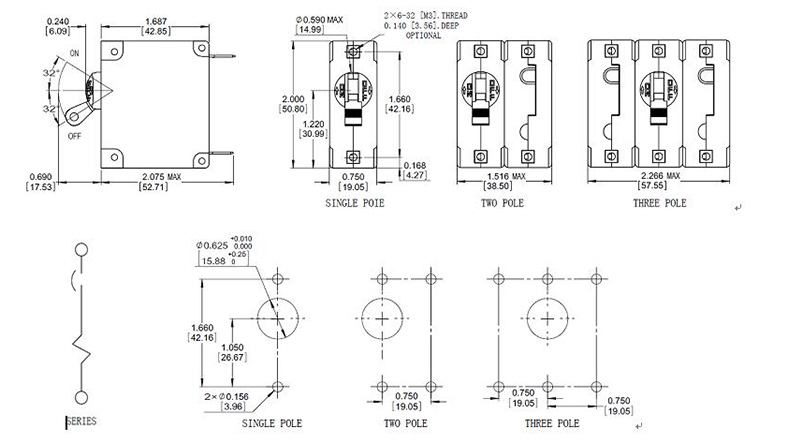

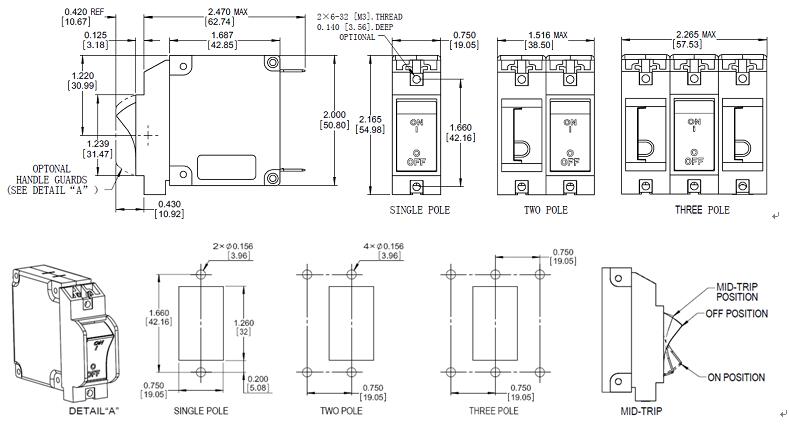

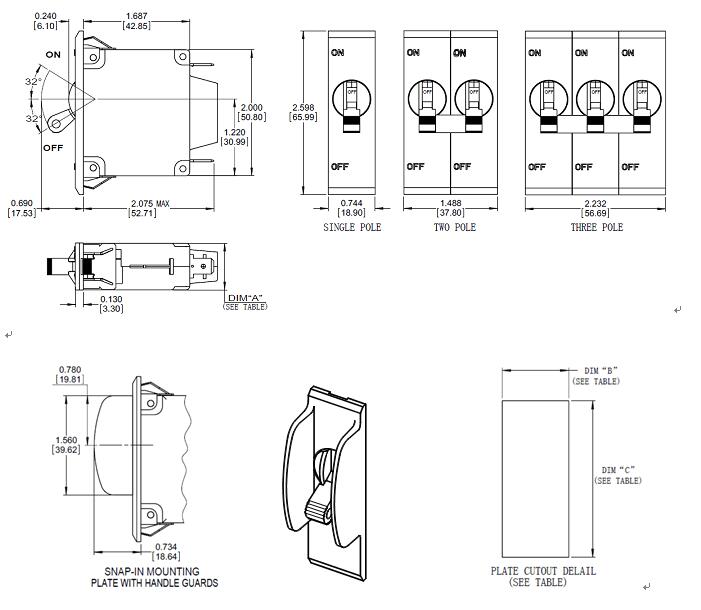

6.1 Toggle handle , Actuator code “ L”, Mounting method “ M/U”, Outline dimensions (Tolerance ±0.02in[.51mm] Unless noted), Mounting dimension (Tolerance ±0.005in[.13mm] Unless noted)

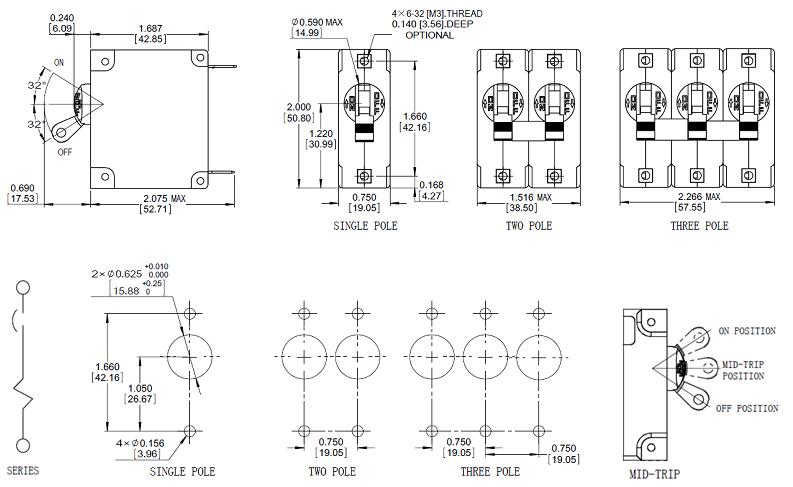

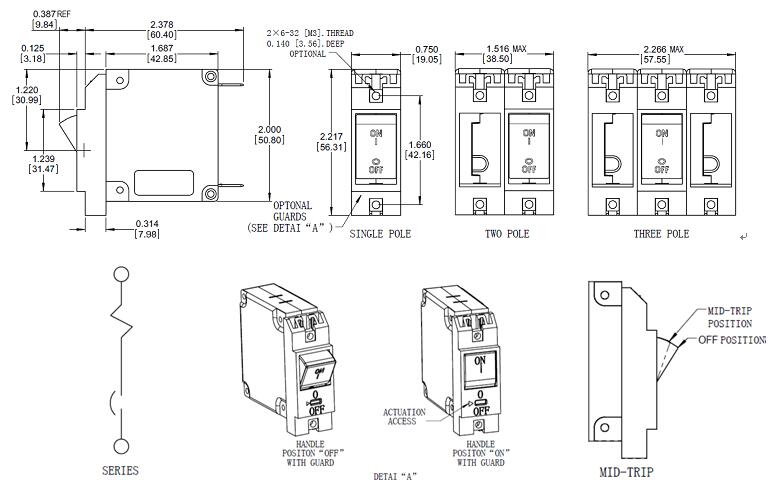

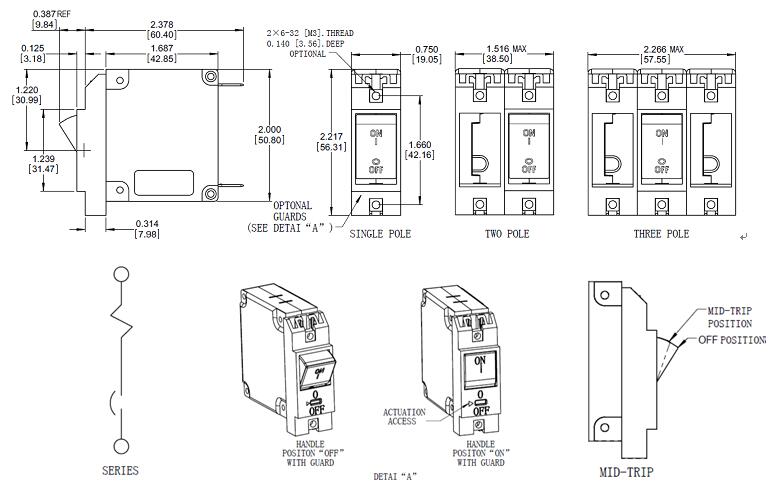

6.2 Toggle Handle,Actuator code “ S”, Mounting method “ M/U”,Outline dimensions (Tolerance ±0.02in[.51mm] Unless noted), Mounting dimension (Tolerance ±0.005in[.13mm] Unless noted)

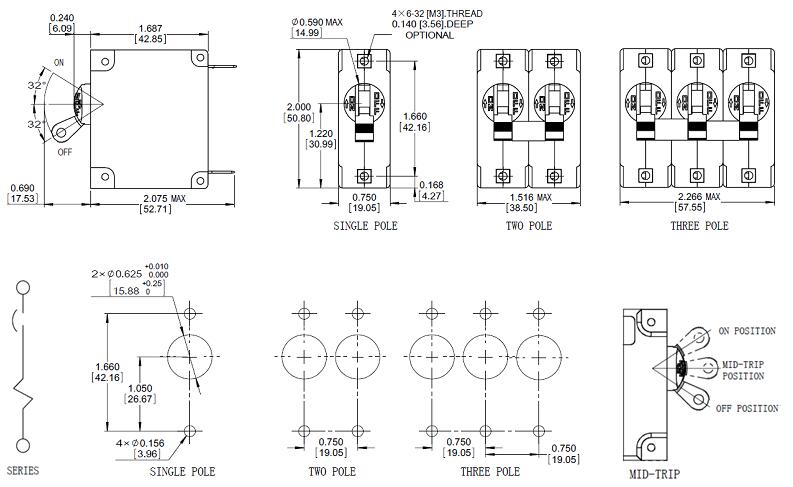

6. 3 Rocker Handle,Actuator code “ Y”, Mounting method “M/U”; Outline dimensions (Tolerance ±0.02in[.51mm] Unless noted); Mounting dimension (Tolerance ±0.005in[.13mm] Unless noted)

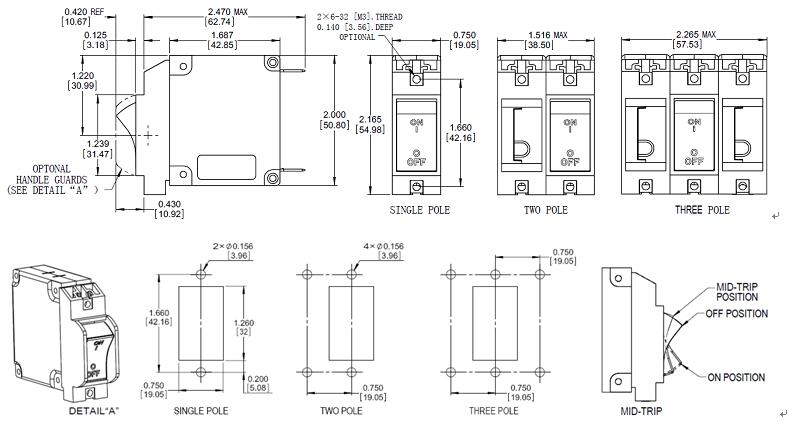

6.4 Flat Rocker Handle, Actuator code “ R”, Mounting method“M/U”; Outline dimensions (Tolerance ±0.02in[.51mm] Unless noted); Mounting dimension (Tolerance ±0.005in[.13mm] Unless noted)

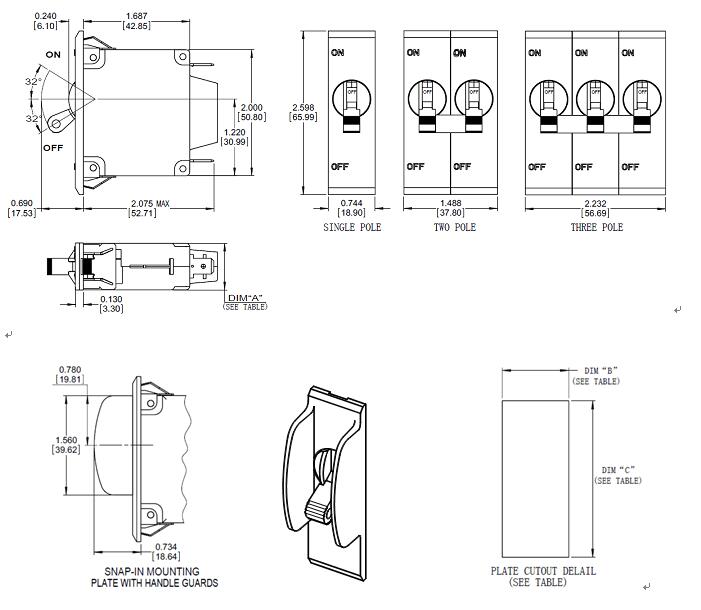

6.5 Toggle Handle, Actuator code “ S”, Mounting method “ Q”; Outline dimensions (Tolerance ±0.02in[.51mm] Unless noted), Mounting dimension (Tolerance ±0.005in[.13mm] Unless noted);

|

3 |

2.266MAX [57.55] |

2.270MIN [57.66] |

2.180±0.005 [55.37±0.13] |

2.186±0.011 [55.52±0.28] |

|

2 |

1.516MAX [38.50] |

1.520 MIN [38.61] |

||

|

1 |

0.750 MAX [19.05] |

0.755 MIN [19.18] |

0.040-0.059 [1.02-1.50] |

0.060-0.100 [1.52-2.54] |

|

POLE |

DIM“A” |

DIM“B” |

PANEL THICKNESS |

|

|

DIM“C” |

||||

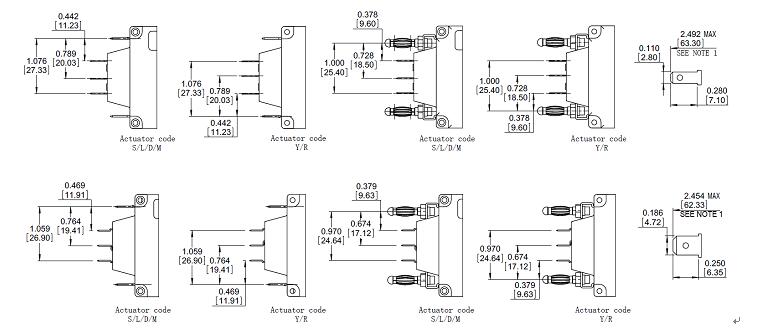

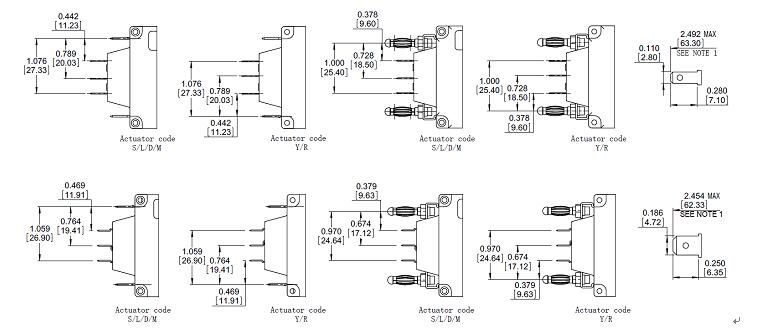

Auxiliary and Alarm Switch

7.1 Outline dimensions (Tolerance ±0.02in[.51mm] Unless noted)

NOTE1:

1: Dimensions That Reference This Note Are Taken From Back of Mounting Panel.

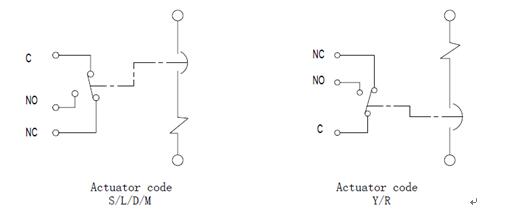

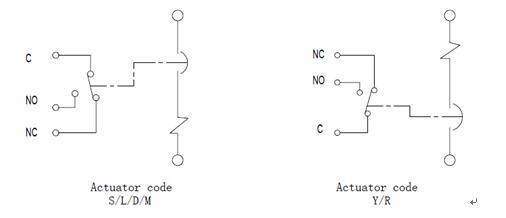

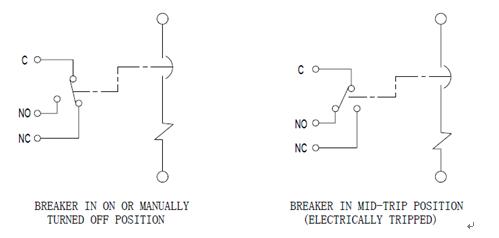

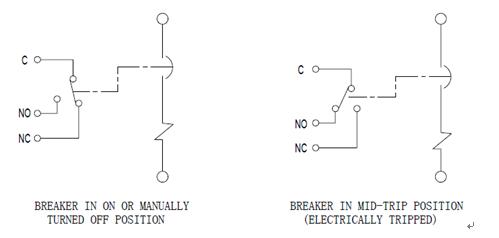

7.2 Auxiliary Switch Circuit diagram

7.3 Alarm Switch Circuit diagram

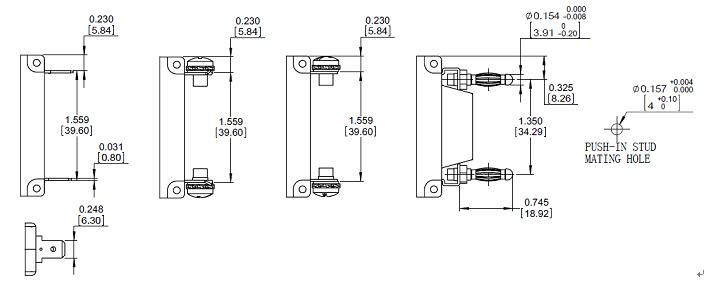

Wiring method and dimension (Tolerance ±0.03in[0.8mm] Unless noted)

Wiring method

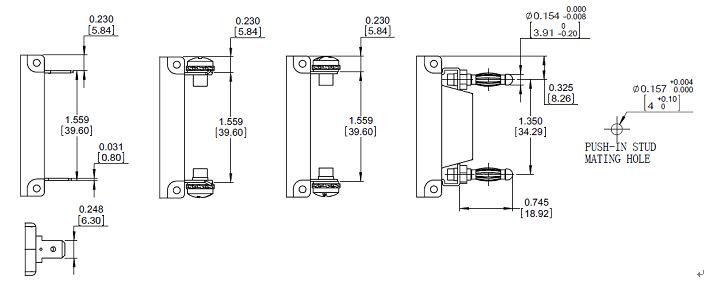

H(≤35A) J/R(≤30A)/F/K P/E(≤30A)/L/G B

Note:During wiring, applied torque on each type screw is shown in following table:

|

Diameter of screw (mm) |

Applied torque (N.m) |

|

M3(6-32) Mounting Screw |

0.5 |

|

M4(8-32) Screw |

1.2 |

|

M5(10-32) Screw |

2.0 |

Packing and depositing

The products should be stored in the warehouse where there are ventilation. The relative humidity there should not exceed 80%, and the ambient temperature there is between -25℃ to +60℃. In addition, there should not be acidic, alkaline and corrosive gas in the air. The products should not be deposited more than 3 years in the above mentioned conditions since the producing date.

Notice

10.1 Do not disassemble the breaker privately.

10.2 Attention to live part when the breaker is energized and avoid touching them.

10.3 Please make sure reliable connection to avoid fault tripping or damage of terminal caused by exceptional heat resulting from unsuitable connection.

10.4 Please maintain the distance of 45mm from the arc jet slot of the product (LINE side) when installation in case there is short circuit breaker due to arc jet.

10.5 The breaker should be mounted within 5° of the mounting plane in case the characters of the product are affected.

10.6 The fasten torque of screw is 0.5N.m.

GET A QUOTE